Graphene oxide enhances ultrafast humidity sensors

A*STAR researchers have designed a low-cost, stable, disposable and ultrafast responsive sensor that is easy to manufacture, overcoming the challenge of producing a simple, fast and highly sensitive version (“Highly Sensitive and Fast Response Colorimetric Humidity Sensors Based on Graphene Oxides Film”).

Measure and control in humidity levels using accurate and reliable sensors is essential for efficient manufacturing and storage practices as well as everyday life.

The A*STAR-affiliated researchers contributing to this research are from the Institute of Materials Research and Engineering. Fuke Wang and colleagues from the Singapore Institute of Materials Research and Engineering, A*STAR have developed an optical humidity sensor that exploits the unique properties of ultrathin layers of graphene oxide (GO) films.

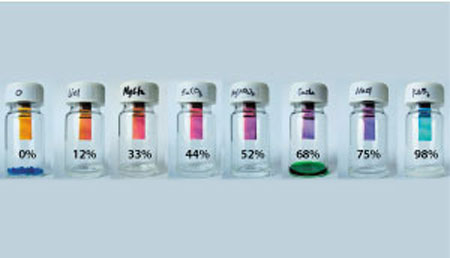

Response of graphene oxide sensor to increase humidity levels. (© ACS)

The new Graphene oxide humidity sensors unlike most humidity sensors, which are electronic and require a power supply, GO-based colorimetric sensors respond to humidity levels by changing color that can be easily observed. For greater accuracy, the change in color can be quantitatively measured by analyzing the reflection spectra of the sensor. Because the GO sensor operates at the atomic level, it can rapidly respond to moisture changes so gives more accurately results.

Exploiting the atomic properties of GOs can only occur if films of uniform thickness can be fabricated, thickness influences the response time and uniformity determines the quality of the sensor.

The research team overcame this challenge by using a process, in which a substrate is dipped in and out of a solution at a constant speed.

“We focused on optimizing the solution viscosity, the substrate-surface treatment and the dip-coating conditions,” explains Wang, “this showed that we can now easily control the thickness of uniform films of GO with a process that is scalable and also generates zero waste.”

The low-cost, non-toxicity and rapid response of GO sensors makes them ideal as disposable sensors. They can be incorporated into food packaging, where humidity levels need to be strictly controlled for storage, for medical instrumentation and semiconducting device manufacturing and storage, as well as environmental monitoring. Their disposal also has no environmental impact.

“We are now exploring further increases in efficiency and sensitivity, and the application to other vapors and gases,” says Wang.