Flexible graphene OLED builds rollable screens

Flexible graphene OLED builds rollable screens

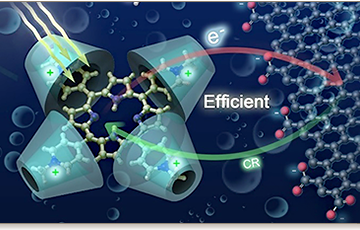

Flexible organic light-emitting diodes (OLEDs), built upon a plastic substrate and Graphene-based organic light-emitting diodes (OLEDs) have received greater attention lately for their use in next-generation lighting, displays that can be bent or rolled while still operating, mainly due to their promise for highly flexible light sources. However, their efficiency has been, at best, similar to that of conventional, indium tin oxide-based counterparts.

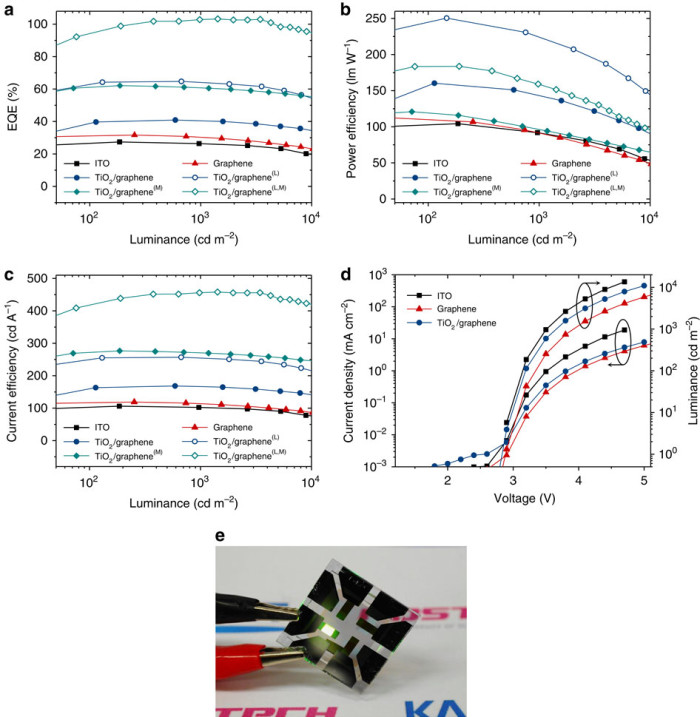

Researchers from Korea’s KAIST institute led by Professor Seunghyup Yoo from the School of Electrical Engineering, KAIST and Professor Tae-Woo Lee from the Department of Materials Science and Engineering, Pohang University of Science and Technology (POSTECH) developed a rollable OLED device that uses graphene(TE) which is placed in between titanium dioxide (TiO2) and conducting polymer layers. The research results were published in Nature Communication. The researchers say that the new OLED is much more durable when bent compared to current devices made with ITO electrodes.

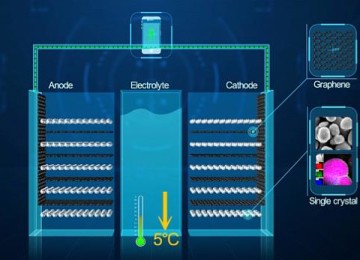

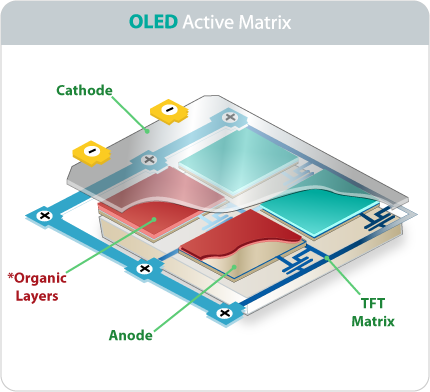

OLEDs are stacked in several ultra-thin layers on glass, foil, or plastic substrates, in which multi-layers of organic compounds are sandwiched between two electrodes (cathode and anode). When the voltage is applied across the electrodes, electrons from the cathode and holes (positive charges) from the anode draw toward each other and meet in the emissive layer. OLEDs emit light as an electron recombines with a positive hole, releasing energy in the form of a photon. One of the electrodes in OLEDs is usually transparent, and depending on which electrode is transparent, OLEDs can either emit from the top or bottom.

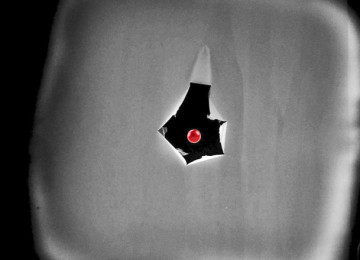

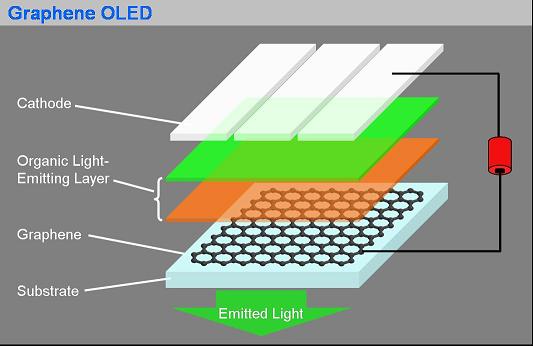

Graphene OLED structure

In conventional bottom-emission OLEDs, an anode is transparent in order for the emitted photons to exit the device through its substrate. Indium-tin-oxide (ITO) is commonly used as a transparent anode because of its high transparency, low sheet resistance, and well-established manufacturing process. However, ITO can potentially be expensive, and moreover, is brittle, being susceptible to the bending-induced formation of cracks.

Graphene, a two-dimensional thin layer of carbon atoms tightly bonded together in a hexagonal honeycomb lattice, has recently emerged as an alternative to ITO. With outstanding electrical, physical, and chemical properties, its atomic thinness leading to a high degree of flexibility and transparency makes it an ideal candidate for TEs. Nonetheless, the efficiency of graphene-based OLEDs reported to date has been, at best, about the same level of ITO-based OLEDs.

Performance of OLED graphene Transparent Electrodes (TEs)

Form-factor advantages such as flexibility and stretchability have brought organic light-emitting diodes (OLEDs) great attention for use in emerging devices like wearable, roll-type or foldable displays that call for mobility, deformability and/or expandability1, 2. The full realization of such potential, however, is non-trivial and requires significant effort in various aspects such as a development of low-temperature thin-film transistor technologies and/or flexible encapsulation3. Another important aspect to consider for highly flexible displays is to find Transparent Electrodes (TEs) that can replace indium tin oxide (ITO) electrodes, which typically suffer from limited flexibility and potential cost issues associated with high demand and/or unstable supply4. In this regard, several kinds of flexible transparent electrodes such as metal nanowires, carbon-based materials (for example, carbon nanotubes or graphene) and metal grids coupled with other types of TEs were proposed for OLEDs