Graphene aerogel gets new technique to producing by 3D printing

3D print manufacturing the graphene aerogel

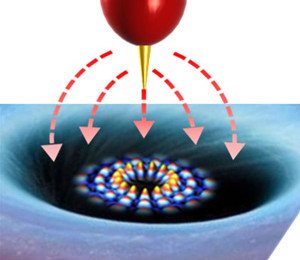

American researchers from Kansas State University and The State University of New York at Buffalo have developed a new technique for 3D printing graphene aerogel with complex microstructures. The technique combines drop-on-demand 3D printing with freeze casting.

Aerogel is useful for many applications because of aerogel low density, light weight and spongy materials that can be used as both thermal and optical insulators and can potentially be used as batteries and catalysts within electronic components, as of recent years, can be produced with certain 3D printers. Graphene aerogel is perhaps the pick of the bunch, as they can potentially be used as batteries and catalysts within electronic components. Remember the first ever 3D printed graphene supercapacitor on which we reported a few weeks ago? A 3D printed graphene aerogel was used to make it.

Researchers in Buffalo and K-State developed a new 3D printing technique for producing graphene aerogel, which the researchers hope will open up new uses and applications for the material. Developing the method was no easy task for researchers, however, since graphene is notoriously difficult to manipulate. “For the previous method, you need to change the viscosity of graphene to be really high in order to print, which blocks the way to reduce the weight of printed graphene aerogel,” said by Dong Lin and Chi Zhou, assistant professors at K-State and Buffalo and lead authors of the paper “Three-Dimensional Printing of Graphene Aerogel.”

The most widely adopted method for producing graphene aerogel involves using an inkjet printer to extrude a mixture of graphene and polymers or silica. The unwanted polymers or silica can afterwards be burned away or removed with a chemical process, but both of these steps can potentially damage the graphene structure. As with many 3D printing applications, it can also be difficult to produce a structure with overhangs. The team, therefore, wanted to develop a new method of 3D printing graphene aerogel, one which could accommodate more complex structure such as those with overhangs.

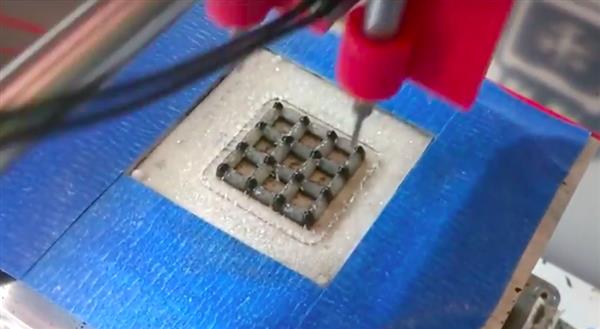

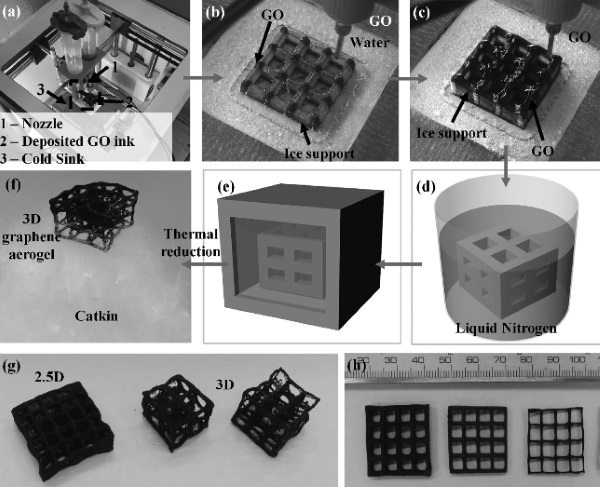

Steps for producing Graphene aerogel by new technique of 3D printing

The technique developed by the Buffalo and K-State researchers eliminates the problems typically associated with 3D printed graphene aerogel, by incorporating freeze casting into the 3D printing process. Where the dominant method tends to be carried out at high or room temperatures, the team 3D printed their aerogels at -25°C. In such a cold environment, each layer froze after printing, allowing the team to build up an ice-supported graphene oxide (GO) structure. With each newly deposited layer of graphene oxide, the unfrozen material melted the frozen top layer. This allowed the layers to mix freely before refreezing in the cold environment, a process which improved the structural integrity of the 3D print by encouraging the formation of hydrogen bonds. A second printer nozzle filled with only water was used to create ice supports for the structure.

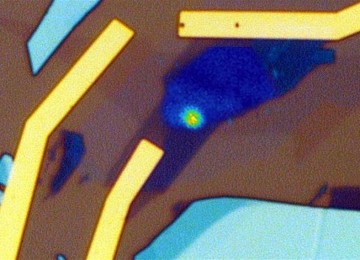

The 3D printed graphene aerogel was finally freeze-dried in liquid nitrogen to get rid of all of the water deposited by the second printer nozzle, before being thermally reduced to graphene. The team was able to 3D print aerogels with densities ranging from 0.5 to 10mg/cm3, each with good electrical conductivity and high compressibility.

“It’s certainly an interesting technique” commented Andrea Ferrari, director of the graphene centre at the University of Cambridge, UK. “Additive manufacturing is quite widespread for prototyping and it is good to have graphene available to do this type of work.”, now many researchers hope to build on their findings by investigating the possibility of creating aerogel structures formed of multiple materials.