Graphene-Silver nanowires builds future touch screen

Graphene-Silver nanowires builds future touch screen

The field of nanomaterials vying to replace indium tin oxide (ITO) as the transparent conductor that controls display pixels in touch screen displays is getting crowded. We’ve seen materials including carbon nanotubes, silver nanowires, and graphene promoted as the heir apparent for this application.

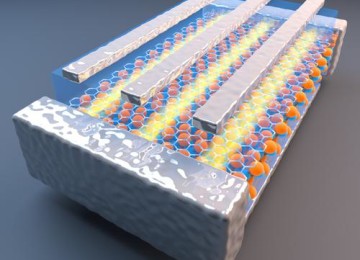

Now, researchers at the University of Sussex in England have introduced a strong contender into the battle to replace indium tin oxide: a hybrid material consisting of silver nanowires that are linked together with graphene.

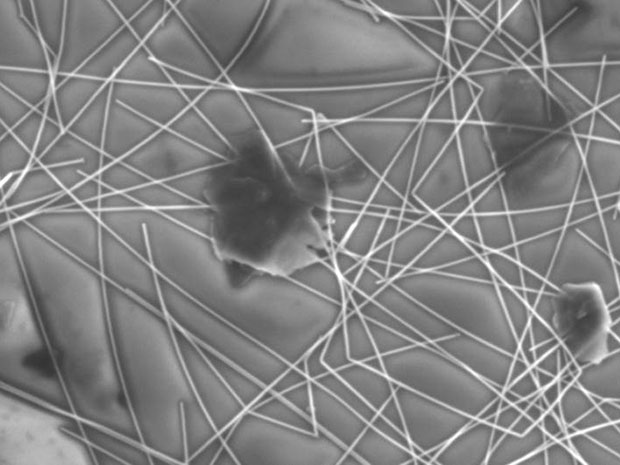

“The hybrid material is a lot cheaper due to the fact that we only need to use a fraction of the nanowires normally required to attain the properties of ITO,” explained Alan Dalton, a professor at the University of Sussex and whose lab conducted the research, in an e-mail interview with IEEE Spectrum. “The graphene acts as linkers between the nanowires, which means that the network does not need to be dense. We deposit the graphene onto a sprayed network of nanowires by film deposition.”

The reduced costs associated with this hybrid material versus silver nanowires on their own opens up the potential of it taking a larger share of the transparent conductor market; it’s been predicted that demand for these conductors will push sales past the $900 million mark by 2025.

Graphene-silver nanowires

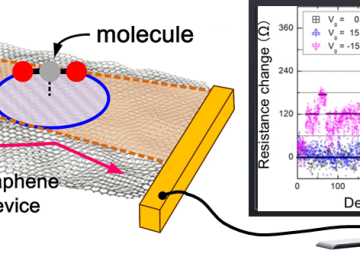

In research described in the journal Nanoscale, the researchers showed that the key to producing the material is a mathematical technique that has been used previously to describe how phase changes like freezing happen in very small spaces.

“In this research we have applied a mathematical technique to work out the smallest subpixel size we can make without affecting the properties of our nanowire electrodes,” explained Matthew Large, lead author of the paper, in a press release. “The results tell us how to tune our nanowires to meet the requirements of any given application.”

Silver nanowires have proven to be one of the most promising replacements to ITO. Companies such as Cambrios and Blue Nano are among the most notable commercial ventures leveraging this technology.

“Silver nanowire and silver nanowire–graphene hybrids are probably the most viable alternatives to existing technologies,” said Dalton in a press release.

Dalton believes that their new process will reduce not only reduce the production costs associated with these materials, but also reduce the energy demands of the materials, giving it both a price and performance advantage over competitors.

Dalton and his lab have joined forces with M-SOLV, based in Oxford, England; together, they are looking to apply these latest research results to commercial projects.