Graphene uses to convert car engine heat into electrical energy

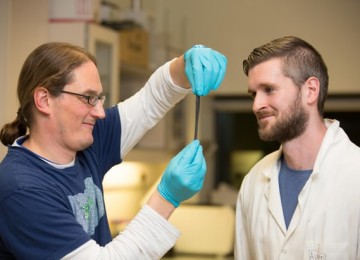

Scientists and researchers from the UK, including ones from Manchester University, used graphene to develop a material that could convert an engine heat into electrical energy to help keep a car running (instead of lost and going to waste) and reduce the need for fuels. It could also have applications in aerospace, manufacturing, and other sectors.

One approach scientists are exploring to help address these issues involves capturing waste heat from engines and other power systems and turning it into electricity. Many compounds can do this but are heavy, costly, toxic or only operate at high temperatures. Ian A. Kinloch, Robert Freer, and colleagues sought new alternatives.

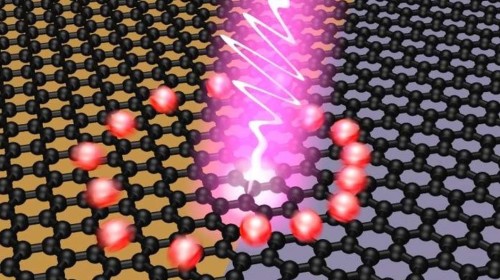

Compounds that are able to capture waste heat from engines and other power systems and turn it into electricity are usually heavy, costly, toxic or only operate at high temperatures. The scientists in this study took a material called strontium titanium dioxide and added a small amount of graphene. The resulting composite was able to capture and convert heat into electric current efficiently over a broad temperature range.

Graphene uses to convert car engine heat into electrical energy

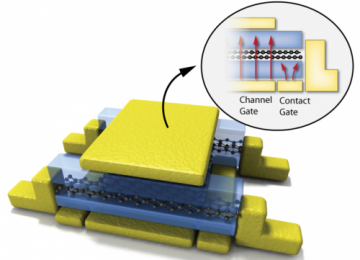

The resultant materials were reduced and possessed a multiphase structure with nanosized grains. The thermal conductivity of the nanocomposites decreased upon the addition of graphene, whereas the electrical conductivity and power factor both increased significantly. These factors, together with a moderate Seebeck coefficient, meant that a high power factor of ∼2500 μWm–1 K–2 was reached at room temperature at a loading of 0.6 wt % graphene. The highest thermoelectric figure of merit (ZT) was achieved when 0.6 wt % graphene was added (ZT = 0.42 at room temperature and 0.36 at 750 °C), with >280% enhancement compared to that of pure LSTO. A preliminary 7-couple device was produced using bismuth strontium cobalt oxide/graphene-LSTO pucks. This device had a Seebeck coefficient of ∼1500 μV/K and an open voltage of 600 mV at a mean temperature of 219 °C.

As car manufacturers are constantly looking for ways to improve their fleets’ average fuel efficiency, such a material can be extremely valuable.

In 2012, the US government announced fuel-efficiency standards that would require U.S. vehicles to average 54.5 miles per gallon by 2025. Improving gas mileage could help reduce greenhouse gas emissions and global dependence on fossil fuels.

Improving gas mileage could also help reduce greenhouse gas emissions and global dependence on fossil fuels, It could also have applications in aerospace, manufacturing, and other sectors also.