Laser-induced graphene makes 3D microsupercapacitors

3D microsupercapacitors can uses in flexible devices show potential for use in wearable and next-generation electronics

Graphene and its derivatives are versatile building blocks for bottom-up assembly of advanced functional materials. In particular nanotechnology and electronics parts with an exceptionally large specific surface area, excellent electrical conductivity, and superior chemical/electrochemical stability, graphene represents the ideal material for various electrochemical energy storage devices including supercapacitors.

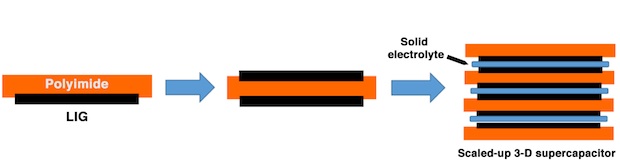

Rice University scientists advanced their recent development of Laser Induced Graphene (LIG) by producing and testing stacked, three-dimensional supercapacitors, energy storage devices that are important for portable, flexible electronics.

The Rice lab of chemist James Tour discovered last year that firing a laser at an inexpensive polymer burned off other elements and left a film of porous graphene, the much-studied atom-thick lattice of carbon. The researchers viewed the porous, conductive material as a perfect electrode for supercapacitors or electronic circuits.

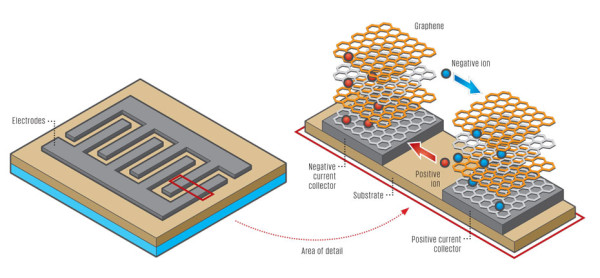

Their work to make vertically aligned supercapacitors with laser-induced graphene on both sides of a polymer sheet. The sections are then stacked with solid electrolytes in between for a multilayer sandwich with multiple microsupercapacitors, it have ripples, wrinkles and sub-10-nanometer pores in the surface and atomic-level imperfections give LIG its ability to store a lot of energy.

A schematic shows the process to make 3D microsupercapacitors by LIG tech

They select graphene material because of graphene retains its ability to move electrons quickly and gives it the quick charge-and-release characteristics of a supercapacitor. In testing, the researchers charged and discharged the devices for thousands of cycles with almost no loss of capacitance.

What we’ve made are comparable to microsupercapacitors being commercialized now, but our ability to put devices into a 3-D configuration allows us to pack a lot of them into a very small area,” Tour said. “We simply stack them up.

So we can see this tech to make supercapacitors in markets soon the reason is that we’re doing this very simply. Nothing about the process requires a clean room. It’s done on a commercial laser system, as found in routine machine shops, in the open air.

The flexible stacks show excellent energy-storage capacity and power potential and can be scaled up for commercial applications. LIG can be made in air at ambient temperature, perhaps in industrial quantities through roll-to-roll processes.

LIG supercapacitors appear able to do all that with the added benefits of flexibility and scalability. The flexibility ensures they can easily conform to varied packages – they can be rolled within a cylinder, for instance – without giving up any of the device’s performance.