New Graphene composites for 3D Printing Uses

New Graphene composites for 3D Printing Uses

3D printing is a rapidly growing field. It consists in the deterministic layer-by-layer printing of 3D objects of almost any shape, from a Computer Aided Design source file. Its versatility, the limited number of process steps and reproducibility, make 3d printing one of the most promising techniques for rapid design and prototyping.

Graphene composites for 3D Printing:

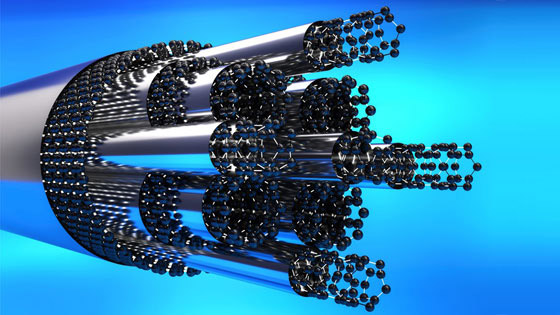

EU researchers have created and tested a range of new polymer composites based on graphene and speciality graphites. They are expected to use in the consumer electronics and automotive industries, Graphene has unique extreme properties seemed to herald a whole host of exotic materials and Graphene’s electrical, thermal, optical and mechanical properties, Among its many attractive properties, graphene is extremely strong and conducts both heat and electricity. Only small amounts of added graphene can create polymer composites that also possess these properties than the starting materials.

“We’ve seen some exciting properties on a lab scale but we still don’t have a large number of applications for these sorts of materials,” says Ben Hargreaves of NetComposites Ltd, a consultancy specializing in industrial composites.

“Where graphene is exciting people is the possibility of doing several things at once,” Hargreaves says. “For example, could we enhance electrical properties, mechanical properties and thermal properties simultaneously using a single additive?”

Until recently, progress had been held back by a restricted supply of good-quality graphene and a lack of knowledge and experience in using it in new kinds of applications.

Graphene composites 3D Printing have many Uses

When NanoMaster started in 2011 graphene was available in batches of only 50 grams but one of the partners, Avanzare, is now turning out batches of 25 kilograms in several different grades that are available commercially.

This improved supply allowed the partners to create and test many new materials by combining different grades of graphene and speciality graphites with different types of polymer. Many are supplied as ‘masterbatches’ – highly concentrated additives already mixed with a polymer that can then be blended with other materials on production lines. This allows manufacturers to use their existing processes, such as injection moulding, with little modification.

The four-year project finished late in 2015 and discussions are continuing on how to introduce some of the new materials into existing product lines. Three of the partners – Philips (consumer electronics), Röchling (automotive components) and LEGO (toys and games) – have run trials to explore the use of graphene composites in their own products.

“The idea is that these materials can either replace metal components – thereby reducing weight and potentially costs – or can replace existing polymer components, allowing part thickness to be reduced whilst also providing improved functionality,” Hargreaves says.

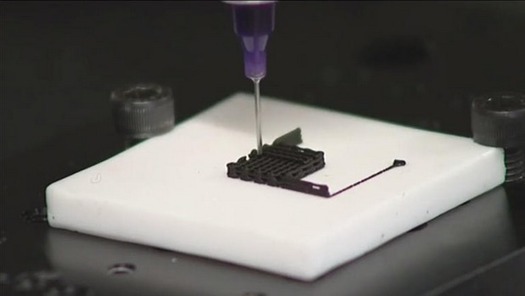

Graphene composites also lend themselves to additive processes such as 3D printing. “With a 3D printed heat exchanger you can potentially design – print in – a much more efficient flow path than you could otherwise achieve with a machined metal equivalent,” he explains.

The project has also developed a body of good practice for working with these new materials, not least in health and safety. Graphene is classed as a ‘high aspect ratio nanomaterial’ (HARN) and therefore has the potential to present similar hazards to materials like asbestos, so the partners have devised safe working practices for handling and cutting graphene composites.