New method to produce high-quality graphene sheet with single-crystal

New method to produce high-quality graphene sheet with single-crystal

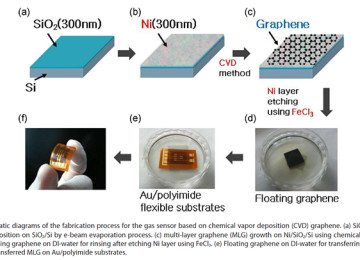

Since had invented making graphene using transition metals such as Copper “Cu” or Nickel “Ni” as a substrate, scientists have realized the preparation of large-area graphene films.

Especially this way simple, low-cost and can present high-quality and large-scale continuous monolayer graphene has been successfully grown on copper foil so this way is a promising way for industrial-level graphene production.

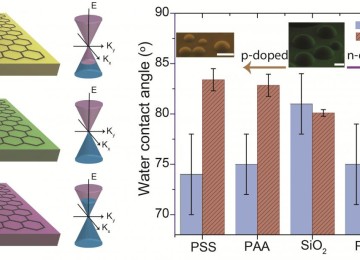

But, the graphene films obtained by this way are usually polycrystalline this polycrystalline makes as randomly oriented graphene islands, which decreases its quality and would greatly degrade the electrical, mechanical, thermal and optical properties. Therefore, to find a method to synthesize large-size single-crystal graphene is a big scientific problem needed to be solved.

How developed this new method ?

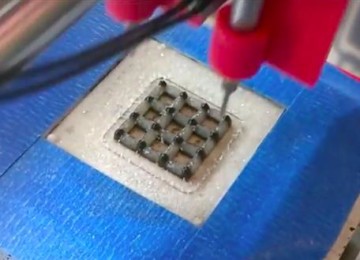

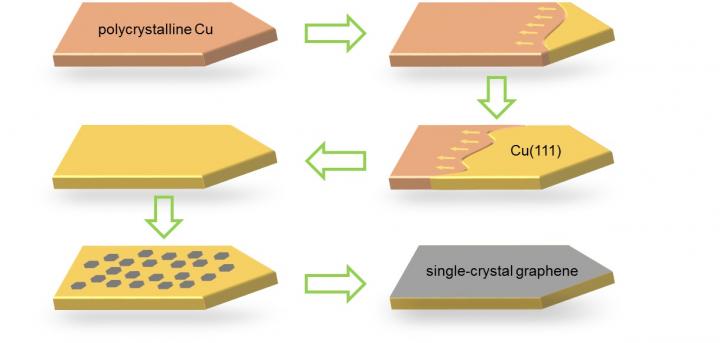

Researchers used thermal annealing using a temperature-gradient-driving technique. The team led by Prof. K. H. Liu, Prof. D. P. Yu and Prof. E. G. Wang from Peking University cooperating with Prof. F. Ding from Ulsan National Institute of Science and Technology and other collaborators found a new way to prepare 5×50 cm2 single-crystal graphene on industrial copper foils.

The researchers grew graphene on the surface of a 5 × 50 cm2 copper foil, which was transformed into a single-crystal copper foil by heating to approximately 1,030 degrees Celsius. A temperature slope from hot to cold moved the so-called grain boundary onward, creating a perfect single crystal. During the heating and cooling treatment, copper atoms migrated inside the material, arranging into an ordered structure with fewer defects.

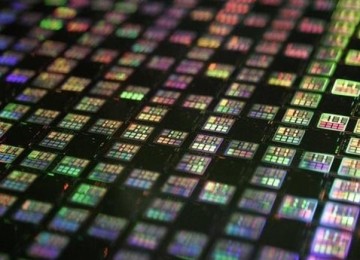

Then, using chemical vapor deposition, millions of parallel graphene islands were formed on the copper foil surface. As more carbon atoms deposit on the foil, the islands kept on growing until they coalesced and formed a very-close-to-perfect single-crystal graphene layer that covered the entire available surface. “The secret to obtaining single-crystal graphene of a very large size is to have a perfect single crystal copper as a base to start with. Large single-crystal copper foils are not available in the market, so labs must build it with their own means,” explained the team.

The team’s findings may allow a leap forward in graphene production, advancing from a technique that synthesizes a few square centimeters of single-crystal graphene in a couple of hours to an optimized method that allows the creation of an almost-perfect (> 99.9 percent aligned) 5 × 50 cm2 single-crystal graphene in just 20 minutes. Moreover, the low production costs, comparable to commercially available lower quality polycrystalline graphene films, could expand its usability.

This reported technique allows the synthesis of large-size single-crystal graphene films, which possess superior properties for various high-end applications, especially in electronics, such as large-scale fabrication of THz devices and the transparent film replacing Indium Tin Oxide “ITO” can used for many applications, such as flat-panel displays, smart windows, polymer-based electronics, thin film photovoltaics, and architectural windows. Moreover, ITO thin films for glass substrates can be helpful for glass windows to conserve energy. It will also enable the epitaxial growth of various other 2D single-crystal materials on graphene with meter-sized dimension.