Printed graphene with lasers new tech for flexible electronics

Printed graphene with lasers new tech for flexible electronics

Everyday scientists and researchers have new steps to make wearable devices and intelligent gadgets available in life fields but need cross too many challenges to make it suitable and low-cost.

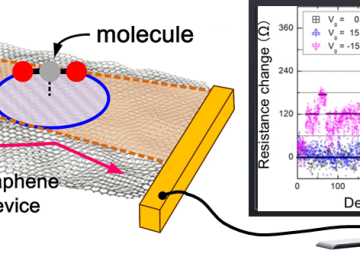

Researchers in Jonathan Claussen’s lab at Iowa State University used inkjet printers to print multi-layer graphene circuits, had the researchers work to using it for flexible, wearable and affordable electronics.

But existing technology has problems because it needs usually high temperatures or chemicals to printed graphene had to be treated to improve electrical conductivity and device performance, but both treatments could degrade or destroy flexible or disposable printing surfaces such as plastic films or even paper.

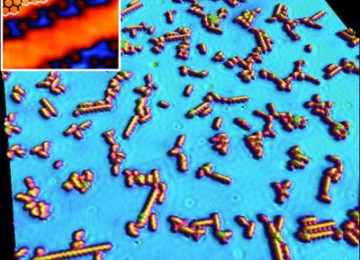

The researchers found to solve this problem by using pulsed-laser process to treating inkjet-printed, multi-layer graphene electric circuits and electrodes that improve electrical without damaging the graphene or the substrate because the laser works with a rapid pulse of high-energy photons They heat locally. They bombard locally. They process locally. So that do not destroy paper, polymers or other fragile printing surfaces.

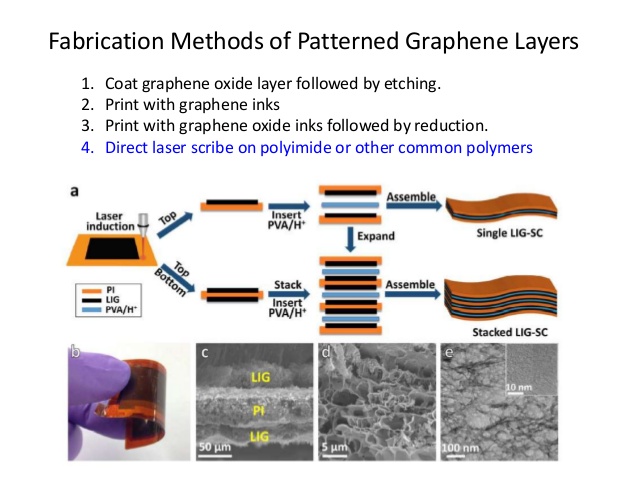

In the last year, researchers from the university of Manchester teamed with researchers in BGT Materials Limited company, invent another way to improve printed Graphene for flexible electronics by without resorting to a binder because binder needs high temperatures destroy materials like paper or plastic. They invent this by the first printing and drying the ink without any heating, and then compressing it with a roller, similar to the way new pavement is compressed with a road roller.

The compression treatment increasing printed graphene conductivity by more than 50 times, and the resulting “graphene laminate” was also almost twice more conductive than previous graphene ink made with a binder.

Laser pulses print multilayer graphene circuits

Using pulsed laser process to treating printed graphene makes electrical conductivity more than a thousand times better. and researchers developed computer-controlled laser technology that selectively irradiates inkjet-printed graphene oxide. The treatment removes ink binders and reduces graphene oxide to graphene physically stitching and collecting together millions of tiny graphene flakes.

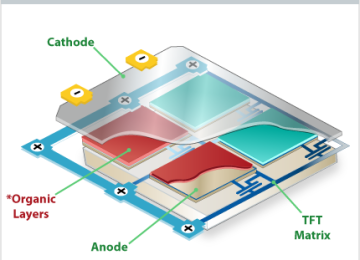

This new tech paves the way for not only paper-based electronics with graphene circuits but can it enables the creation of low-cost and disposable graphene-based in radio-frequency identification (RFID) tags and wireless sensors, fuel cells, electrochemical electrodes for myriad applications including sensors, biosensors, and medical devices.