Scientists use bacteria with 3D printer to produce graphene

Scientists use bacteria with 3D printer to produce graphene

Researchers at the Delft University of Technology in the Netherlands are using 3D printed bacteria to create bespoke, graphene-like materials. They say that bacteria 3D printed in precise lines can ‘pull’ oxygen atoms off graphene oxide, turning it into a material that is more like graphene.

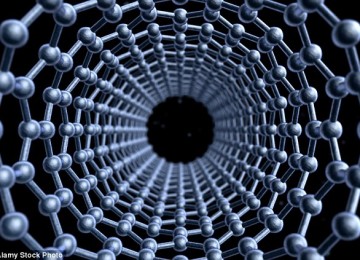

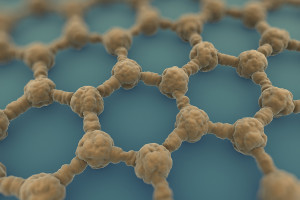

Graphene is a thin layer of pure carbon atoms and is both the lightest material and the strongest compound is known to man. The material is therefore highly desirable, but obtaining it is extremely difficult. Traditionally, making quality graphene has been an expensive and slow process involving the use of toxic chemicals. It still is, but while it may be a long time before graphene becomes easy to produce, researchers at TU Delft have developed a 3D printing method that can be used to create a material that is actually pretty close to graphene.

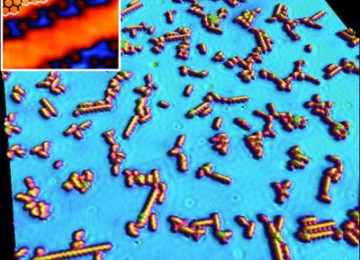

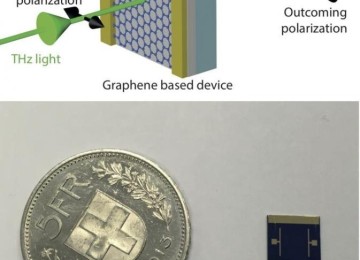

The secret to the new technique is 3D printed bacteria, to be precise. The researchers have discovered that bacteria can be deposited in precise lines using a 3D printer to turn graphene oxide a compound of carbon, oxygen, and hydrogen into a material that closely resembles graphene. The trick is getting these bacteria to “reduce” the graphene oxide, by pulling oxygen atoms off the material as they metabolize. This process of reduction can also be achieved with heat or chemicals, but the researchers say that bacteria is cheaper and more eco-friendly.

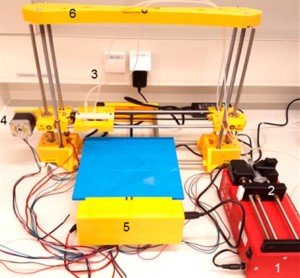

The bacteria 3D printing system

The researchers hacked an ordinary desktop 3D printer to make it print bacteria onto a surface in precise lines just 1 millimeter wide. Printing bacteria is no mean feat, of course, and the researchers had to make a special concoction of E. coli mixed with a gel made from algae. They 3D printed this cocktail onto a dish containing calcium ions, and these calcium ions make the gel solidify upon contact. This keeps the bacteria exactly where they need to be.

The innovative researchers say that you could eventually 3D print a graphene-oxide-reducing bacterium, called Shewanella one Dennis, onto the material in specific patterns to tailor its physical properties. Excitingly, all this is relatively easy to orchestrate, since no extreme temperatures or toxic chemicals are needed. “The more you reduce [graphene oxide], the closer it is to graphene,” said Dr. Anne Meyer, a bionanoscience researcher at TU Delft. “It’s very easy: it takes place at room temperature in some sugar water.”

Meyer says that, once the bacteria 3D printing technology is improved, it could be used to add tiny conductive wires into the graphene oxide surface, leaving the rest non-conductive. This would make it much easier to precisely deposit the bacteria solution to the graphene oxide. The researchers also want to see if the process could be used to modify substances present in lunar dust. This, they say, could be useful for building electronic devices in space.

The researchers’ findings have been published in ACS Synthetic Biology, in a paper called “A Straightforward Approach for 3D Bacterial Printing.” The findings will also be presented at the Microbiology Society’s annual conference which takes place in Edinburgh, UK, in April.