Vorbeck producing graphene-enhanced rubber with engineered HNBR

Vorbeck producing graphene-enhanced rubber with engineered HNBR

After announcing its collaboration with Reliance last month, to develop graphene-enhanced rubber and elastomer materials, Vorbeck Materials launches Vor-flex engineered HNBR elastomer rubber reinforced with Vor-x Graphene and called first elastomer product “Vor-flex 50”.

The Vor-flex 50 has a nominal tensile strength of 3500 psi and a Shore A hardness of 88.“Vor-flex’s high-temperature stability allows it to serve in some of the most demanding environments, such as those found in automotive and petrochemical applications,” said Founder and President of Vorbeck Materials. “Vor-flex is also an ideal choice for making custom gaskets to serve in severe applications as it provides a very tough seal, resistant to chemicals and fuels”.

The Vor-flex 50 is planned to be the first in a new family of graphene-enhanced, engineered elastomer products made using Vorbeck’s proprietary Vor-x technology. Vor-x provides Vor-flex 50‘s hydrogenated nitrile butadiene rubber (HNBR) with extreme strength at low deformation (high modulus) and the ability to withstand temperature from 0˚F and spikes up to325+˚F above the rated working temperature of HNBR.

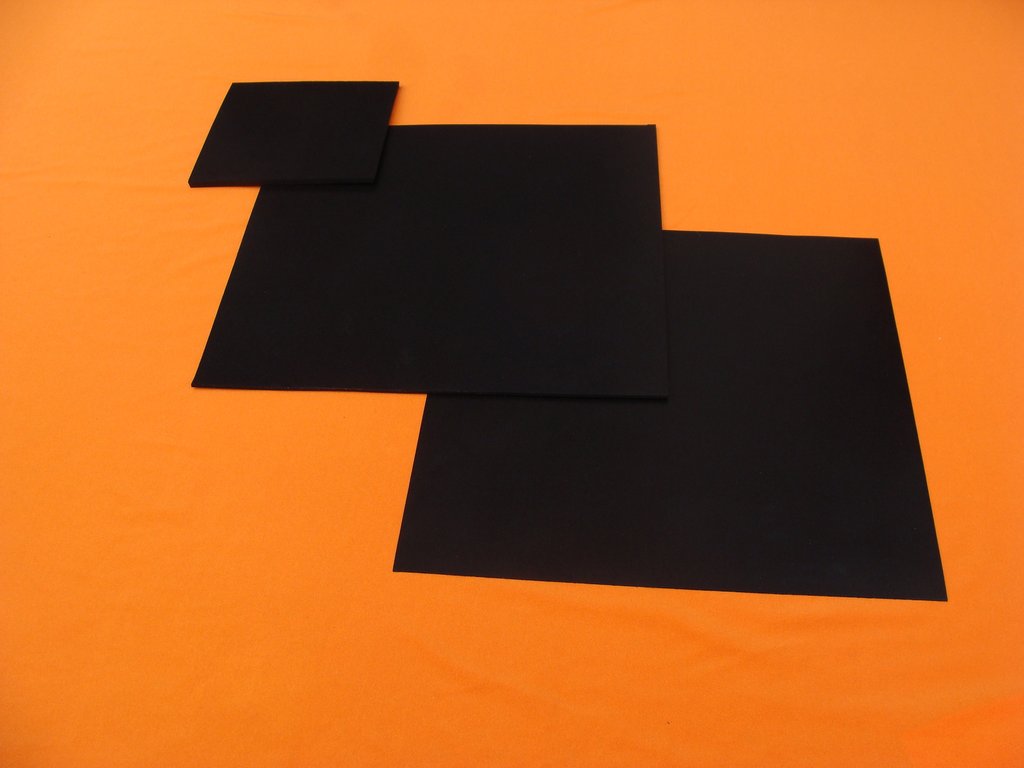

Vor-flex™ 50 is available for purchase online in a variety of commercially relevant sizes of sheets at Vorbeck store .

Vorbeck Materials

About Vorbeck Materials :

Founded in 2006, Maryland-based launched what they claim to be the world’s first commercial graphene-based product, Vor-ink™, in 2009. The Company has taken in just over $20 million so far from Fairbridge Venture Partners, Stoneham Partners, and the U.S. Department of Energy. Vorbeck’s patented graphene material was developed by University of Princeton chemical engineers Ilhan Aksay and Robert K. Prudhomme with which Vorbeck still collaborates with. Vorbeck is the first and only company to receive EPA approval for the commercial production and sale of graphene-based products, developing graphene-based solutions based on their Vor-X single-sheet graphene. Vorbeck develops and offers graphene-based inks (such inks were used the first ever graphene-based product, the Siren anti-theft packaging device.), composites, coatings and graphene-enhanced batteries. Vorbeck also develops graphene-based batteries.

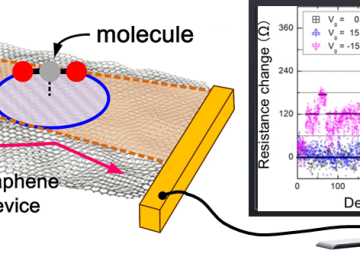

Vorbeck’s products Vor-x® is Vorbeck’s proprietary graphene material which is used in various Vor-ink™ formulations. Vor-ink™ is a graphene-based conductive ink that can use for a large number of applications including printed electronics.

As of late 2012, Vorbeck had increased the annual production capacity of Vor-ink™ to over 40 tons. Vorbeck’s online store has various conductive graphene inks for sale ranging from $87.5 to $140 for 500 grams or 1.1 pounds. Taking an average price of $116 per ink can, at 40 tons capacity this would bring in revenues of $8.4 million per year for Vorbeck provided the entire inventory was sold.